Filter solution for sulphuric acid plant SO2 tail gas / NH3 / SO2 tail gas scrubber tower sector - Chemical & Pharmaceuticals - Fine Chemicals

Tail Gas Scrubber Process Information: The SO2 conversion rate of single absorption plants is lower than double absorption, and many single absorption plants installed tail gas scrubbers to reduce this SO2 content rather than convert the plant to double absorption. Scrubbing the tail gas (tail gas scrubbing) to acceptable SO2 emission values can be done with seawater, caustic, lime slurry, hydrogen peroxide or ammonia. After exiting the absorber tower, the gas enters a tail gas scrubber tower where ammonia (NH3) is injected and contacts the SO2. Ammonium Sulphite and Bi-sulphite are formed and some of these salts are entrained in the exit air. These salts are soluble, but can be emitted in quite large volumes, e.g. 2,000 – 15,000 mg/m3 and are generally < 3 microns in size, with a large amount < 1 mircron.

Problems to Solve

Air pollution

- Prevent blockage of fibre bed by salts solidification.

- Occasional risk of weak acid mist emission

Design Solution

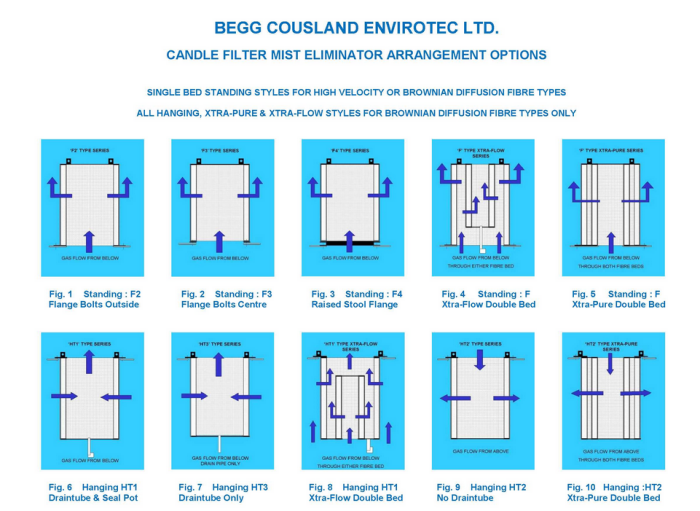

- High Efficiency, Brownian Diffusion ‘Becofil’ Candle Filters, hanging type HT or standing type F, with TGW15 or B14W Glass Fibre elements and Polypropylene or GRP/FRP structure. Option of concentric bed Xtra-Flow F design.

Notes : Pre-wet the inlet gas to solubilise the ammonia salts. Use an irrigation spray system to wash fibre when pressure loss increase indicates blockage is happening.