- Home

- Companies

- ABM Sensor Technology

- Articles

- Hygienic / Sanitary Level Measurement ...

Hygienic / Sanitary Level Measurement for the Pharmaceutical Industry

Pharmaceutical manufactures require accurate and reliable monitoring of level, mass or volume inside storage and process tanks to operate efficiently, avoiding downtime and production losses. ABM’s sanitary, non-contact level sensors and non-invasive level switch meet the demands for hygienic pharmaceutical applications.

- Inventory Management: Liquids, powders and granular materials level in storage tanks for proper management and reduced production downtime

- Process Control: Level in process tanks for control of ingredient quantities during mixing, blending, and reaction processes

- Safety: Monitoring and preventing overflows, spills, and equipment damage

Sanitary / Hygienic Level Sensors

- Continuous, self-adjusting non-contact level sensors

- Measure liquids, slurries or solids in any sanitary application without fail

- Self-cleaning and maintenance free operation

- Withstand high temperature and high pressure processes - CIP for 1/2 hr.

- Optional Remote Monitoring Platform to monitor level data 24/7 from anywhere, with full remote support from ABM for set-up, sensor performance optimization, diagnostics and troubleshooting

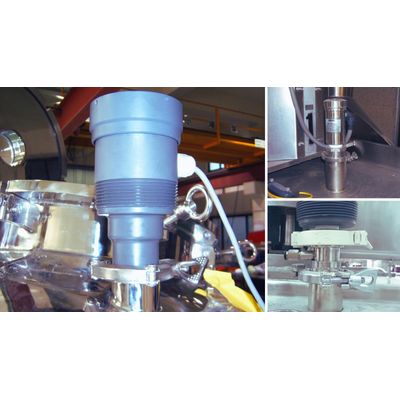

Ultrasonic Sensor

ABM's sanitary ultrasonic sensor is designed with a 316L stainless steel transducer face with 1 1/2" or 2" tri-clamp mounting for sanitary applications. Optional stainless steel or Teflon nozzles can be used for process temperature up to 266°F (130°C) and 5 bar maximum pressure rating. Learn more >

Radar Sensor

ABM's sanitary radar sensor is designed with a Food Grade Teflon antenna with 2" tri-clamp mounting ideal for sanitary applications with gases, vapors (i.e. CO, CO2) or foaming. The sensor antenna can withstand a process temperature up to 400°F (204°C) and a maximum pressure rating of 2 bar. Learn more >