A. Berents GmbH & Co. KG products

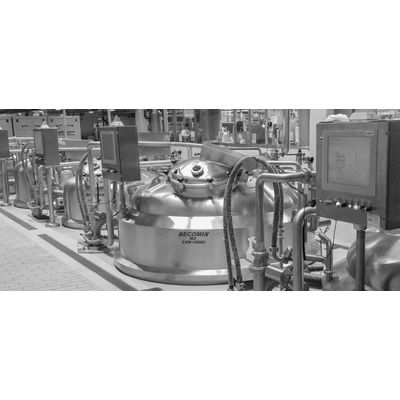

BECOMIX - Large Volume Low-Cost Processor for Viscosity Control

The LVM processor is engineered for the swift and economical production of products with low to medium viscosity. It is adept at handling a variety of applications, such as cough syrup manufacturing with main mixer RW 6600 S, featuring several pre-phases and storage tanks, and recipe-guided control with CIP/SIP automation via PROMAS CS Batch. In ophthalmics, it's seen with RW 600 CD for sterile processes. Its versatility stretches to suspensions, sterile injections, and numerous other products including shampoos, sun sprays, and hair dyes. The system integrates technologies like shear variability, hot/cold production, and precise raw material dosing. With advanced features including membrane valves for sterile processes, direct powder moistening, and inline process measurement, the LVM processor ensures high efficiency and compliance with pharmaceutical standards.BECOMIX - Laboratory Homogenising Mixer for Pharmaceutical Applications

The Laboratory Homogenising Mixer from BECOMIX is meticulously engineered to simulate large-scale production processes at a reduced scale, supporting various pharmaceutical and cosmetic applications. It offers shear variability, diagonal mixing, and hot/cold production capabilities, essential for creating high-quality emulsions and dispersions. The mixer is ideal for producing ointments, nano-emulsions, and pharmaceutical creams with precision. Its design includes features for sterile processing, such as integrated CIP/SIP systems and membrane valves. The mixer supports IQ/OQ and CFR 21 Part 11 compliance, ensuring adherence to pharmaceutical regulations. It also incorporates technologies like Powder Jet and inline raw material dosing. With options for automatic raw material dosing and recipe-guided control through PROMAS CS Batch, this mixer is equipped for efficient and automated production. The compact design allows for flexible batch processing and a comprehensive range of applications including gels, nasal sprays, and skin care products.

BECOMIX - Universal Homogenising Mixer for Cosmetic and Pharmaceutical Production

The universal homogenising mixer from BECOMIX is designed for versatile cosmetic and pharmaceutical applications, catering to various product forms such as ointments, nano-emulsions, gels, and creams. This mixer boasts diverse technological capabilities including shear variability for fine-tuning the mixing process, diagonal mixing for uniform product consistency, and both hot and cold production processes. The system supports pharmaceutical qualification, making it suitable for the production of sterile and sensitive formulations, such as sterile injection preparations and ophthalmics. Key features include the use of membrane valves, inline metering, and direct powder processing, enhancing processing efficiency and product safety. Additionally, the equipment offers a comprehensive automation suite through PROMAS CS Batch, which enables recipe-guided control and detailed process measurement. The BECOMIX mixer accommodates large production volumes with equipment like the RW 6600 S and integrates advanced technologies like CIP/SIP and Powder Jet Technology for optimal hygiene and process control.