DAEMC products

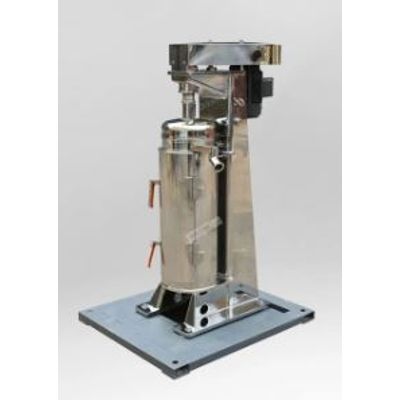

Disk Centrifuge Separator

DAEMC - Biopharmaceutical Separator for Fermentation Broth Purification

The OHC biopharmaceutical separator is integral to the pharmaceutical industry, focusing on the separation and treatment of fermentation liquids. This high-tech equipment serves as a cornerstone in the purification, extraction, and concentration processes within the biopharmaceutical field. By ensuring efficient separation, the device enhances the quality of pharmaceutical products derived from fermentation broths. This technology is crucial in the biopharmaceutical sector, facilitating the development of advanced medical therapies and treatments. Its role extends to various stages of drug manufacturing where precision and reliability are paramount. The separator's performance impacts the efficacy and safety of pharmaceutical products, making it a key asset in the industry. Biotechnology's identification as a critical and emerging sector highlights the importance and relevance of such advanced technological solutions. The OHC separator addresses the rigorous demands of the industry, providing effective solutions that support innovation and progress in biopharmaceutical applications.