Komax AG products

Testing & Quality Tools - Cable & Harness Quality Tools - Integrated Quality Monitoring

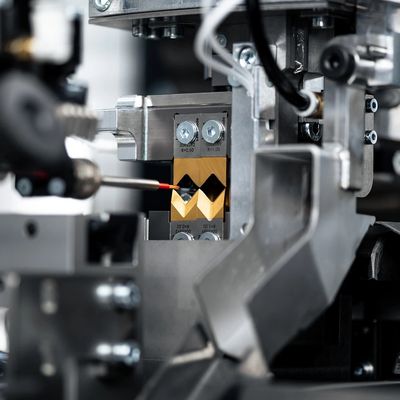

Komax - Model AIC - Adaptive Incision Control System

The Adaptive Incision Control (AIC) system regulates the incision diameter during the production ensuring an optimized stripping process. It reduces setup time, eliminates scrap and downtime. The Adaptive Incision Control (AIC) system continuously compares the defined maximum incision notch depth with the actual cut on the wire. It automatically adjusts the incision diameter and compensates for wire tolerances. Wire ends exceeding the permissible notch depth are reliably detected and sorted out. The standard operating range covers cross sections from 0.13 to 6 mm². Full or partial stripping of any wire length is possible. AIC minimizes the need for manual adjustments and requires only minimal setup. This ensures high-quality results while significantly reducing scrap and unplanned downtimes. The system is available on the Alpha 550 G2 platform and will be introduced to other ACD-compatible machines.

Testing & Quality Tools - Cable & Harness Quality Tools - Visual Inspection

Komax - Model VS35 - Vision Test

With a compact design, the VS35 is the smallest vision system. It has been developed as an assembly and testing station for fuse and relay carriers using cameras for detection. The vision system VS35 offers tests in two steps that can be used to verify certain characteristics of installed components. The first test involves recording a camera image of the test object and evaluating it using the Vision Studio nx test software. This enables the system to check whether the test item equipment is fitted with the correct components. The second test involves using a line laser, and a linear unit for height control. This helps to test the correct insertion depth of the components.The system offers several features, including the ability to run individual test sequences, ease of handling without requiring expert knowledge, standardized interfaces, efficient and safe testing, and the ability to use the system with varying light irradiation due to partitioning.

Komax - Model VS70 - Vision Test

The VS70 vision system has a drawer that can hold two medium-sized test items. Correct assembly is checked using a high-end camera and a line laser. The high-end camera the Komax Testing VS70 with the Vision Studio nx test software deliver precise evaluation and high-quality imaging. The VS70 is primarily designed for Vision Test, allowing for the recording of camera images to verify the correct installation of components. It features standardized interfaces and individual test sequences for easy handling. The VS70 can be integrated into automated production lines, making it an ideal solution for various industries, including automotive, electronics, and medical equipment manufacturing. Its compact size and customizable interfaces ensure reliable and accurate testing results, increasing productivity and reducing errors.

Komax - Model VS70L - Vision Test System

The VS70L vision system has a drawer that can hold two medium to large test items with added height for convenience. Correct assembly is checked using a camera and a line laser. The high quality images of the camera can be easily evaluated using the Vision Studio nx test software. The VS70L performs both Vision Test and Height Control Test to ensure the proper installation and insertion depth of components. The system is efficient and easy to use due to individual test sequences and standardized interfaces. Its partitioning feature allows it to be used in environments with varying light irradiation. It is suitable for industries such as automotive, electronics, and medical equipment manufacturing, and can be customized to meet specific requirements. Overall, the Vision System VS70L from Komax Testing is a versatile solution for component verification. Its ease of use, accurate testing results, and adaptability make it a valuable addition to any production line.

Komax - Model VS100 - Vision Test System

The vision system VS100 has a drawer for placing one large to extra large test items. Correct assembly is checked using the camera and the line laser. The Vision System VS100 from Komax Testing offers highly advanced, precise and high-speed component verification. Its camera provides detailed images for easy and efficient evaluation using the Vision Studio nx test software. The VS100 can test for the correct installation of components, the correct insertion depth of components, and carries out surface inspection tests. Configurable interfaces make the VS100 customizable and suitable for integration into automated production lines, allowing for efficient testing. Despite its advanced features, it is easy to use, with standardized interfaces and individual test sequences. Overall, the Vision System VS100 is an ideal solution for a variety of industries, including automotive, electronics, and medical equipment manufacturing.