- Home

- Companies

- LVD Biotech

- Services

LVD Biotech services

Capabilities

Manufacturing Services

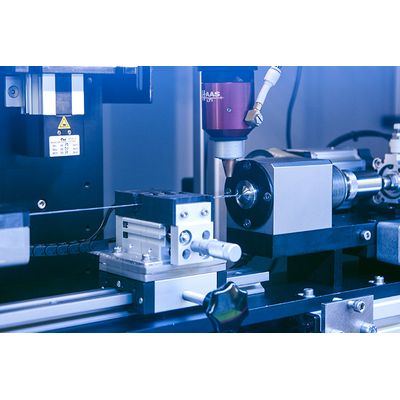

Micro-extrusion: high throughput micro-extrusion facility able to manufacture different tubing designs (single/multi-layer, single/multi-lumen, braided, bump) in many compatible polymeric materials. Production of a wide size range of tubing in compliance with the highest quality standards. Located in an ISO-7 cleanroom. Fully automated and online controlled. Balloon: Formation of a balloon from a polymeric tube through the application of heat, stretch and gas pressure within a wide range of sizes to satisfy customer needs in terms of usability and compliance.

Assembly Services

Welding: Capacity to join different types of tubes, balloons or polymeric radiopaque markers together with a smooth transition. We work with standard welding in hot boxes or with high precision laser welding depending on product requirements and customer needs. Tipping: Adding a non-traumatic soft polymeric tip to a catheter of the balloon catheter using high-precision laser welding. Flaring: Widen the tip of a tube with a heated needle in order to assemble it into another tube.

Pre-Clinical Trials Services

Capability to test our manufactured products in vivo in swine model.

LVD Biotech Services

Fast-track Manufacturing Services

Urgent manufacturing of small orders ensuring prompt delivery.

Regular Production Services

Bulk manufacturing of batch orders of a certain number of units under standard delivery periods and conditions.