Natoli Engineering Company, Inc. products

Natoli Engineering - Tablet Compression Tooling

Natoli Engineering, recognized as a leader in tablet compression tooling, offers specialized punches and dies crafted through advanced micro-precision engineering. With a half-century of experience, Natoli manufactures tooling for all shapes and sizes, maintaining high quality through the use of superior materials. They hold a vast inventory, with over 16 different grades of punch die steel, ensuring consistent quality and prompt availability. Natoli’s offerings include press-specific tooling compatible with nearly any tablet press machine available, and they provide custom designs and specialty coatings to extend tool life and enhance product yield. Their tooling solutions cover various configurations like carbide-tip, multi-tip, and rotating heads, among others, ensuring global availability. Natoli Engineering is dedicated to research and quality assurance, underscoring their commitment to crafting efficient and durable tooling that meets industry standards.

Natoli Engineering - Single-Station Tablet Press for R&D

The NP-RD10A single-station bench top tablet press is a sophisticated instrument designed for laboratory research and development, particularly when only small quantities of active pharmaceutical ingredients (APIs) are available. This compact device provides precise control over tablet parameters, such as hardness and weight, meeting specific production requirements. Its sensitivity enables researchers to gain critical data from minimal API samples, making it a robust choice for teaching in both R&D labs and universities. Featuring a quick tooling changeover of under two minutes, it minimizes material waste by requiring only a single tablet for comprehensive analysis. Additionally, the Natoli AIM™ Pro Data Acquisition & Analysis Software, preloaded on a portable laptop, efficiently analyzes parameters like compression and ejection forces from tablet press operations. This capability facilitates the identification and rectification of formulation challenges, streamlining the overall research and development process.Natoli Engineering - Feeder Base Leveling System for Tablet Presses

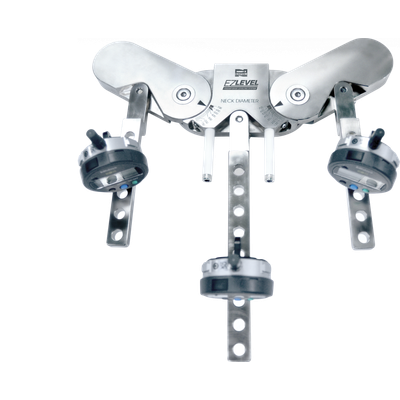

The Natoli EZ Level Feeder Base Leveling System is designed to enhance the precision and efficiency of tablet press machinery. Traditional manual leveling can be inaccurate and time-consuming, leading to potential equipment damage and product defects, such as metallic contamination and tablet discoloration. Natoli's system offers an innovative solution by providing accurate leveling of the feeder platform, ensuring uniform tablet production and minimizing formulation loss. This patented technology not only safeguards critical manufacturing components but also improves overall production consistency and quality. By implementing the EZ Level system, manufacturers can significantly reduce operational downtime and protect against costly damages, while maintaining the integrity and quality of their products.Natoli Engineering - Tablet Press for R&D and Pilot Production

The NP-RD30 is a versatile tablet press designed for research and development as well as pilot production. It combines the efficiency of a full-scale production press with the analytical capabilities necessary for R&D. This multifunctional machine is engineered to support both the manufacturing of small clinical batches and the initial phases of new product development. It includes AIM™Pro data acquisition and analytical software, which streamlines formulation and process development while minimizing production challenges during scale-up. The NP-RD30 is capable of compressing heavy tablets effortlessly, maintaining consistent force even at high RPMs. The machine's design is particularly beneficial for technical teams focused on precision and repeatability. These features make it an ideal choice for laboratories needing efficient data analytics and reliable performance during product development stages.