- Home

- Companies

- Orthoplastics Ltd

- Products

Orthoplastics Ltd products

Medical Implant

For over 40 years, UHMWPE has been the chosen material to use within the production of medical implant applications. Ultra-high-molecular-weight polyethylene, otherwise known as UHMWPE, has been relied upon due to its high resistance to abrasion and wear, including its incredibly strong and durable properties. Its high abrasion resistance and toughness means that it is an exceptionally attractive solution to the complexities of wear. Orthoplastics manufacture UHMWPE from Celanese GUR® 1020, 1050 and 1020-E polymer.

Crosslinking

A direct consequence of industry leading research and development activities has allowed Orthoplastics to successfully ensure that they have the capability to manufacture crosslinked UHMWPE. The benefit of manufacturing UHMWPE in this manner, is a significant reduction in wear on the medical application. By using a process which exposes standard UHMWPE to ionising radiation, it allows Orthoplastics to produce a higher grade of UHMWPE, otherwise referred to as Crosslinked UHMWPE, bringing major benefits to medical implant manufacturers, and the patient community.

Component Machining

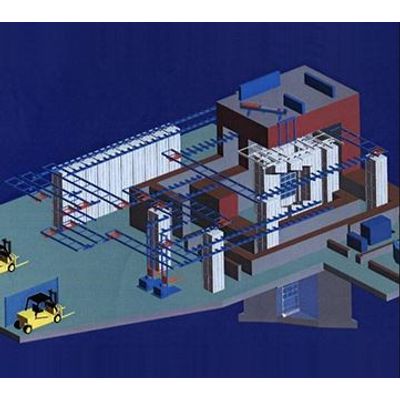

Work with a world leader in implantable plastic manufacturing and component machining. For over 20 years Orthoplastics has established itself as the number one choice to transform orthopaedic component concepts into reality. As a world leader in implantable plastic manufacturing and component machining they have the expertise to navigate customers through the complexities of production, compliance and accreditation, getting medical component products to market quickly and saving customers valuable time and money.