Resonetics products

Laser-Cutting

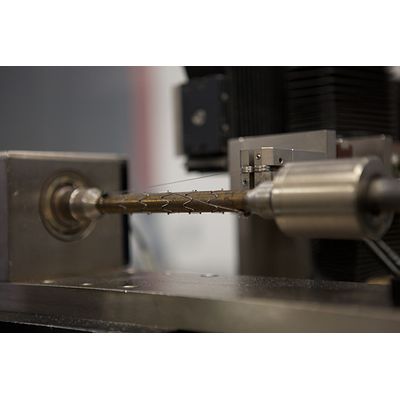

Shape Setting

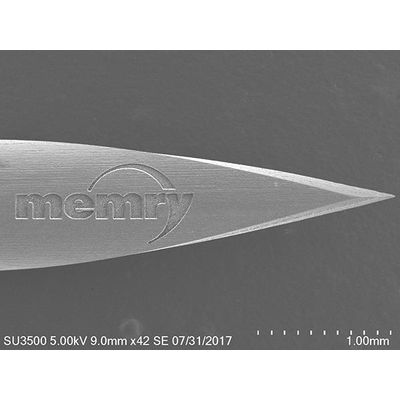

Grinding

Surface Finishing

Lightspeed Application Development Lab

PRIME Laser Cut - Laser Cut - Medical Tubing

Equipped with the latest in technology advancements, our machines are capable of the most precise and fastest cutting speeds in the medtech industry. Our streamlined manufacturing facility is built to expedite the laser cutting process. All procedures are in constant visual communication, nothing is hidden. The unprecedented cutting speeds allow for the minimization of wasted movement and time which equates to higher quality with lower manufacturing costs.

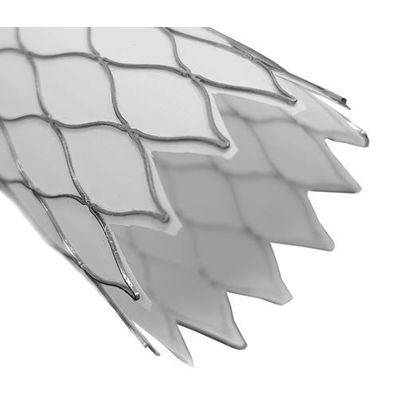

Medibrane - Polymeric Biomaterial Covering

MEDIBRANE Polymeric Coverings are customized biomaterial coverings and coatings for medical frame-based applications such as stent coverings and coatings.

Resonetics - Medical Electromechanical Sensor

Resonetics continuously invests in novel technologies to further our expertise, such as in our Electromechanical Sensors for MedTech. We manufacture custom sensors for critical applications in the life sciences.

Micrablate - Model 3D - Laser Machining

Resonetics` three dimensional or 3D Laser Machining process picks up where traditional mechanical machining and molding processes leave off.