- Home

- Companies

- Tegra Medical

- Products

Tegra Medical products

Tegra - Wire and Sinker

Highlights: Achieve high accuracy and reproducibility with tight tolerances. Burr-free geometries. Machine complex shapes. Micro hole-drilling. .004- to .012-inch wire.

Tegra - Laser Processing Technology

Highlights: Laser cutting – tubular and flat components. Laser welding - work with all metals and miniature components. Laser marking - marking and engraving to apply custom depth marks or logos. Laser drilling - burr-free holes to .002 inches. Laser abrasion (or knurling) - abrade surfaces prior to bonding, molding, and spin welding. Echogenic patterns.

Tegra - CNC Grinding

Highlights: Create myriad shapes and facets in multiple presentations. Robotic material handling and automated inspection for reproducible product and finish. Complemented by our thru-feed, in-feed, and electrochemical grinding.

Tegra - Metal Forming

Highlights: Swaging, bending, flaring, and coining. Sheet metal stamping. Augmented by nitinol shape setting.

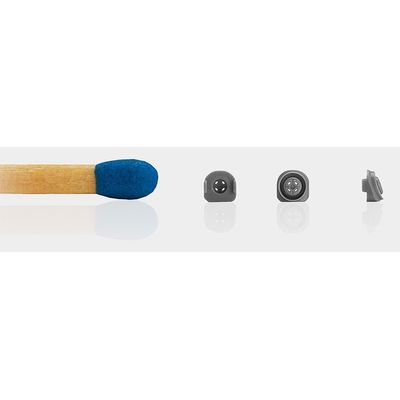

Tegra - Micro Molding

Highlights: Micro injection-molded parts in millions of variations. Components weighing under 0.00004 oz (0.001g). Thin-wall molding with wall thicknesses as thin as 0.006 in (0.15 mm). Components molded consistently and with extreme precision. Expert, in-house mold building and decades of experience.

Tegra - Two-Shot Molding

Highlights: Combines two different thermoplastics into a single component. Creates complex, multi-color, multi-material components. Consolidates the number of parts. Bonds are stronger than those from joining separate parts after molding. Lower tolerances. Improved repeatability and accuracy. Uses turntable technology, index plate systems, and core-back technology as needed. Expert, in-house mold building and decades of experience. Also known as overmolding and double-shot molding.

Tegra - Nitinol Shape Setting

Highlights: Wire, Tubing, Sheet metal.

Tegra - Gundrilling

Highlights: Accurate, repeatable holes with excellent surface finishes. Straightness tolerances of .001” (.025mm) per foot. Concentricity tolerances of .001” (.025mm) per inch. Hole diameter tolerances of +/- .0005” (.0127mm). Finish tolerances as low as 4 Ra. Burr-free intersections. Consistent reproduction from hole to hole.