- Home

- Companies

- AGF Manufacturing, Inc.

- News

- Comparing AGF’s Heated Cabinets for ...

Comparing AGF’s Heated Cabinets for Drum Drip Freeze Protection

It is February. A dry fire sprinkler system’s auxiliary drain sits quietly in a loading dock. Overnight temperatures drop, water in the drum drip freezes, and the ice cracks the lower ball valve. By morning, the system has tripped, and water discharges onto the floor that is now frozen. The building is now dealing with a flooded and icy loading dock, a disabled fire sprinkler system, and possible business interuptions but this did not need to happen.

In many dry and pre-action systems, the drum drip is not the most complex component, but it is often the most vulnerable. Auxiliary drains, commonly referred to as drum drips, are installed at low points to collect condensation that forms inside the piping and to drain the trapped section of piping. While this moisture accumulation is expected, improper management of condensate presents a significant risk during cold weather conditions.

When water is allowed to collect in a drum drip, and temperatures drop below freezing, the condensate can freeze and expand inside the auxiliary drain piping. This expansion can crack or rupture the drum drip assembly. Once compromised, the dry or pre-action system may trip, allowing water to discharge from the failed drum drip. These failures often result in uncontrolled water release, property damage, system downtime, and increased slip and fall hazards within the facility.

AGF Manufacturing’s COLLECTANDRAIN heated cabinets are specifically engineered to protect drum drips by preventing freezing, managing condensate accumulation, and simplifying inspection and maintenance. Models 5400, 5450, and 5500 offer different levels of protection and automation to match varying site conditions and maintenance strategies.

The COLLECTanDRAIN Model 5400 is a heated, manual auxiliary drain cabinet designed to prevent freezing of drum drips in cold environments.

The cabinet features a thermostatically controlled heater and an insulated steel enclosure that maintains internal temperatures above freezing. A float switch monitors condensate levels and provides an alarm signal when the drum drip needs maintenance. Condensate is retained safely inside the heated cabinet until it is manually drained during regular maintenance.

The Model 5400 is ideal for drum drips that are readily accessible and serviced as part of a regular inspection and maintenance program. It is well-suited for installations such as mechanical rooms, warehouses, parking garages, and industrial facilities where well-trained maintenance personnel can easily access the drain for routine manual operation. The locking steel cabinet also makes the Model 5400 a good choice for areas subject to vandalism or unauthorized access, while still providing reliable freeze protection that aligns with established facility maintenance practices.

The COLLECTanDRAIN Model 5450 adds self-maintaining functionality to further reduce the risk of freeze-related drum drip failures.

In addition to the heated and insulated cabinet and float switch monitoring, the 5450 includes an internal Y-strainer and drain trap. When condensate reaches a predetermined level, excess water is automatically shed while maintaining system pressure. This controlled removal of condensate reduces the volume of water retained in the drum drip, lowering the likelihood of freeze expansion and pipe damage.

The Model 5450 is well-suited for commercial buildings and light industrial facilities where access to drum drip auxiliary drains is limited and frequent manual draining is impractical. It is an effective solution for locations with moderate freeze exposure, where reducing the volume of condensate retained in the system is important. By automatically shedding excess water while maintaining system air pressure, the Model 5450 helps reduce maintenance demands and lowers the risk of freeze-related drum drip failures. This model provides an effective balance between freeze protection and reduced service requirements.

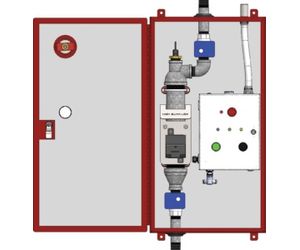

The COLLECTanDRAIN Model 5500 offers the highest level of protection through fully automated drum drip management.

This cabinet includes all freeze protection features of the 5400 and 5450, along with an integrated programmable logic controller that automatically operates supply and drain valves. Condensate is drained based on float switch activation or programmed logic, eliminating reliance on manual intervention. By minimizing the amount of water retained at low points, the 5500 significantly reduces the risk of freeze-related drum drip rupture and unintended system trips.

The Model 5500 is ideal for locations where on-site staff may not be trained or familiar with proper drum drip maintenance procedures. It is particularly well-suited for facilities in severe cold climates, including industrial warehouses, retail garden centers, hospitals, senior living facilities, apartment buildings, and large campuses with multiple auxiliary drains. The fully automated operation makes it an effective solution for areas with restricted access or a history of repeated freeze-related failures. By eliminating reliance on manual draining and reducing human error, the Model 5500 provides maximum reliability for drum drip protection while minimizing labor requirements, system downtime, and the risk of unintended system trips.

For any COLLECTanDRAIN heated cabinet installed in exterior or exposed locations, both the back plate and the protective cover are required. The outdoor cover is Model 5680A, and the mounting plate is Model 5690A. These components protect the cabinet, piping, and electrical elements from environmental exposure such as wind, snow, and rain. Even with internal heating, exterior installations require this added protection to ensure consistent performance and long-term durability of the drum drip assembly.

Drum drips are a critical component of dry and pre-action sprinkler systems, but they also represent a common failure point in cold environments. When condensate freezes and damages a drum drip, the resulting system trip and water discharge can cause significant operational and financial consequences.

AGF COLLECTanDRAIN heated cabinets provide a proven solution by maintaining auxiliary drains above freezing temperatures, controlling condensate accumulation, and reducing the likelihood of drum drip rupture. Selecting the appropriate model allows contractors and facility managers to protect the fire sprinkler system, reduce maintenance risks, and improve overall system reliability.