- Home

- Companies

- Kovalus Separation Solutions, Inc.

- Products

- Kovalus - Model OptiSet 4.1 - ...

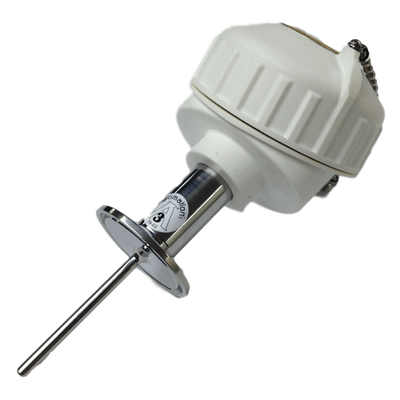

Kovalus - Model OptiSet 4.1 -Coagulation Detection System

The OptiSet 4.1 Coagulation Detection System monitors the curd coagulation process within the vat to identify the “exact instance” of coagulation. Based on input from the cheese maker, the Recipe function on the control panel initiates the cutting of the coagulum when the optimum firmness is achieved. OptiSet also serves as a powerful diagnostic tool, helping the cheese maker to understand the effect of upstream processes on the “exact instance” of coagulation. The system reduces cost, maximizes yields, and provides better consistency from vat to vat.

Most popular related searches

- Optiset software and hardware never requires calibration

- All RELCO supplied equipment is built to applicable 3A standards and USDA guidelines for dairy equipment and governmental regulations in effect as of the date of this quotation unless specifically noted

- Detects the “exact instance” of coagulation within a cheese vat

- Recipes can be created and saved in the program for a variety of cheeses to ensure

- consistent firmness of cut

- Data is displayed for each cheese vat where an OptiSet probe is mounted

- Probe data is stored in a Daily Data Log for review and retrieval to customer’s Scada System

- Early and late coagulation alarms for advanced warning of coagulation problems

- Optiset will identify the variation of coagulation time based on:

- Impact of set temperature

- Impact of changes in milk chemistry

- Impact of type or amount of starter/rennet

- Automatic cutting of coagulum for consistency and firmness of cut

- Typical process improvements include:

- 5% reduction in whey fat loss

- 10% reduction in rennet usage

- Consistent moisture control

- Consistent finished product