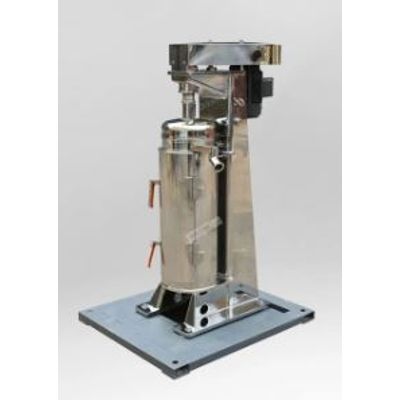

DAEMC - Model W81 -Continuous Tubular High-Speed Centrifuge for Biochemical and Pharmaceutical Applications

The W81 is a continuous tubular centrifuge designed for the rapid and efficient separation of biological and pharmaceutical mixtures on a pilot scale.

W81 flow centrifuges are characterized by the ability to process a volume many times higher than the volume of the rotor. Choosing the right centrifuge for a given application depends on the volume of the substance being processed and its properties.

Liquid mixtures to be separated are supplied from the bottom to the rapidly rotating rotor. Cells and other solid particles are deposited in the rotor, while the liquid is removed in its upper part using a collecting plate. In the case of preparations separated into two liquid phases, a density gradient of the liquid in the rotor is formed and then the liquid is separated into two fractions using two separate collecting plates.

W81 high speed tubular centrifuge is popular used for extraction & purification. In the fields of Biochemical, Edible oil, VCO, Lithium Chloride Solution etc.

- European-made components.

- GMP compliant design and documentation.

- Affordable and reliable.

- Easy to maintance.

- Rapid separations.

- Consistent performance.

- Range of models facilitate scale-up.

- Simple to set up, use and clean for minimal down-time between separations.

- No replacement membranes or costly disposables.

- Small footprint saves space.

- For mixtures with very high solid concentrations, drum centrifuges can be supplied.

- Powerful 3-phase electric motors provide rapid acceleration and quieter operation.

- Permanently-lubricated SKF bearings maintain long service life.