- Home

- Companies

- Gkteso GmbH

- Products

- Gkteso - Model OEM QA - Customized ...

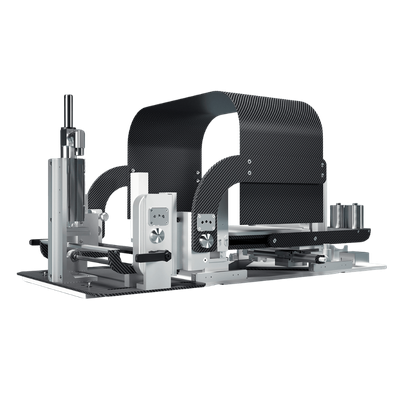

Gkteso - Model OEM QA -Customized Tools

Customized QA Tools from gKteso are OEM-specific, high-precision solutions designed for quality assurance, calibration, and validation in radiation therapy and medical imaging. Developed with RT specific materials, Solid Water (RW3) or actual water reservoirs and radiation-hard machining processes, they deliver reproducible results for LINAC commissioning and advanced imaging applications. OEM-specific contract design, prototyping, and scalable serial manufacturing ensure seamless integration into next-generation systems. With CE/MDR compliance, FDA-ready documentation, and adaptable configurations, gKteso customized phantoms provide reliability, regulatory confidence, and long-term durability for OEM system integration, clinical QA routines, and research environments worldwide. Products include full water phantoms, MR – Laser – CT setup phantoms, MR distortion phantoms and many more.

Customized QA tool from gKteso combine OEM-specific design with high-precision Solid Water (RW3) materials to ensure accurate and reproducible results in radiotherapy and imaging. Each phantom is developed for seamless integration into next-generation systems, from prototype to serial production. With full CE/MDR and FDA ready documentation, these customized solutions deliver lasting reliability for QA, calibration, and clinical validation worldwide.

Standard QA systems often cannot match the complexity of OEM platforms. Custom geometries, integration requirements, and radiation-hard materials are essential for accurate beam validation and long-term stability. These tools fill the gap between prototype and production – ensuring quality assurance, calibration, and reproducibility across global systems.

Customized OEM QA Tools address these challenges with precise, reproducible geometries, radiation-hard materials, and long-term dimensional stability. Each phantom is developed and verified under ISO 13485 development standards to ensure consistent QA performance from prototype to clinical deployment. Full CE/MDR and FDA ready documentation guarantees regulatory confidence for OEM integration and international use.

- OEM-specific design and scalable manufacturing for QA, calibration, and R&D

- Tissue-equivalent Solid Water (RW3) for reproducible dose measurement

- Exclusive designs for OEMs, marketed and labeled under their registration

- Mechanical precision down to 0.02 mm

- Short development cycles through local manufacturing and rapid prototyping from 1 or 5 to several hundred units per year