Expo Process Analytics - Model FFSim -Feed Frame Simulator for Pharmaceutical Process Development

The FFSim™ Feed Frame Simulator from Expo Process Analytics is an advanced laboratory-scale simulation tool designed to enhance pharmaceutical process development. It provides a modern alternative to traditional scale-up facilities by closely mimicking commercial production environments while reducing the consumption of Active Pharmaceutical Ingredients (API). This simulator is instrumental in collecting extensive data that supports Pharma 4.0 initiatives, facilitating rapid development of scalable Process Analytical Technology (PAT) models, and enabling the creation of digital twins. Widely used by leading pharmaceutical innovators, FFSim™ significantly decreases API usage, accelerates process development, and supports Quality by Design and PAT approaches for achieving blend and content uniformity. An example dataset involves the use of FFSim™ with Near Infrared spectroscopy to develop a Partial Least Square calibration model for APAP blends, showcasing high accuracy in predicting blend uniformity even with complex blends. This simulator aids in generating reliable, scalable NIR models and ensuring quality consistency in pharmaceutical manufacturing processes.

Process development is a critical stage in scaling up pharmaceutical manufacturing processes. Time and API is precious in process development and it is critical that all major risk factors are identified before tech transfer to manufacturing. Traditionally, scale up facilities are used in process development. A more modern approach to process development is to use laboratory-scale simulators that closely mimics commercial production but can operate more quickly and with less API. The rich data collected from laboratory-scale simulators supports Pharma 4.0 initiatives through quickly gaining process knowledge, rapidly develop scalable PAT models. These data can also input into digital twins.

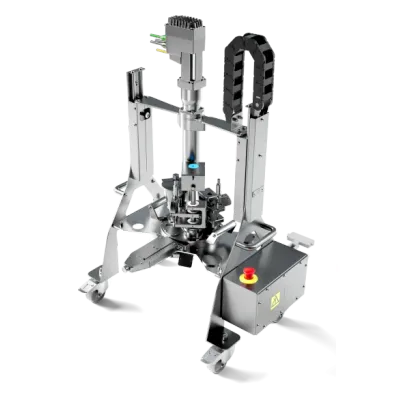

One proven example of a laboratory-scale simulator is the FFSim™ from Expo Process Analytics to simulate tablet press feed frames. Used by the world’s leading pharmaceutical innovators, the FFSim™ reduces API usage, speeds up process development, and enables PAT and Quality by Design approaches for blend uniformity or content uniformity.

Product highlights

- Highly configurable for process development or general powder characterization

- Supports up to two spectroscopic PAT probes, including NIR, Raman, UV, and LIF

- Installation for benchtop, fumehood, or high containment areas

- ~ 300 mL chamber volume reduces material requirements and cGMP equipment usage by 90%

- Configurable inlet and outlet ports for accurate flow-through simulations