Poietis - Model NGB -Next Generation Bioprinting Plaform

Next Generation Bioprinting (NGB) plaform has been developed to overcome current tissue manufacturing methods which are the bottleneck impeding standardisation, scale-up and large-scale market adoption of Tissue-Engineering products. It solves critical limitations of existing 3D bioprinting technologies thanks to single-cell resolution and learning-based methods.

Indeed, largely inspired by the principles of the 4.0 Industry, this new platform integrates automation and robotics technologies, coupled with numerous online sensors – including cell microscopy – and Artificial Intelligence processing. In addition, it integrates all bioprinting techniques (laser-assisted bioprinting, bioextrusion, micro-valve bioprinting), a world’s first in the bioprinting market.

NGB platform integrates a specific « cytocentric », user-friendly CAD software. This software can be used to design the location and local environment of different cell types and materials in three-dimensional tissue structures.

CAD files describe the architecture of biological tissues with the 3D organization of tissue components (cells and extracellular matrix).

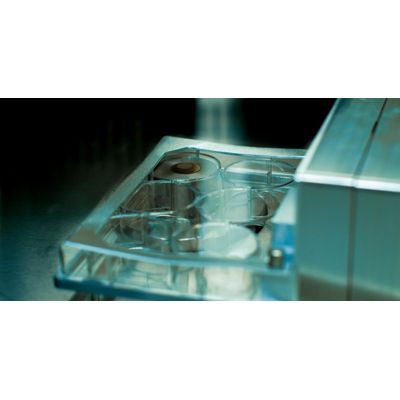

NGB platform integrates a multimodal, easy-to-use bioprinter based on laser-assisted bioprinting capable of 3D-printing tissue components in sterile conditions, with great accuracy and reliability thanks to 6-axis robotic arm and automation. This bioprinter is now the 4th printer version from the beginning of the project in 2005 and the only fully mutlimodal on the market.

Bioprinting technologies have been combined with a specific imaging system coupled with IA machine learning algorithms to confirm that is designed is what is bioprinted.

Data generated at all steps of the process are used to model tissue formation. A dedicated software is now under development to program tissue self-organization, which means to anticipate the evolution of the bioprinted construct with time.