Model CUP-CVP -Specialised Pump

Concrete volute pumps are designed for high flow applications, resulting in fewer pumps. This need for fewer pumps reduces overall civil dimensions considerably. The pump is predominantly produced in concrete, which eliminates potential corrosion problems often experienced in corrosive environments. The pump is constructed as an integral part of the pump-house ensuring consistent civil and mechanical interfaces. After installation almost 100% availability is achieved due to the combination of the slower running speed, minimal wear and exceptional reliability, this also eliminates the need for stand-by units. Concrete volute designs boast a minimum of 10 years between internal inspections. These inspections can be performed within the volute without removal of the pump cartridge.

- Hydraulic efficiency

- Engineered for hydraulic efficiency, typically 2 points higher efficiency than bowl pump

- Cast-in casing

- Cast-in casing, manufactured to suit civil construction programme at site

- Non corrosive

- Concrete volute, hence non corrosive. Ensures concrete in compression, single concrete pour reduces risk of leakage

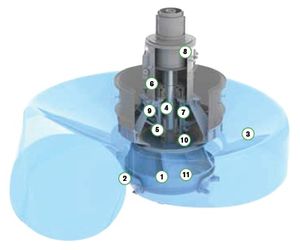

- Inner cartridge

- Complete inner cartridge element designed for ease of installation, can be installed and removed with embedded parts in situ

- Gland + seal

- Packed gland and inflatable seal, designed for ease of maintenance

- Thrust bearing

- Thrust bearing integral with gear housing (gearbox options). Absorbs all hydraulic and static thrusts

- Journal bearing

- Journal bearing oil bath lubricated

- Gearbox

- Optional epicyclic gearbox integral with gearbox and thrust bearing in integral housing. Included with pump cartridge for ease of installation and removal, reduces physical size of motor

- Oil tank

- Oil tank integral with pump bearing bracket

- Cover

- Cover designed for full discharge pressure. Interface between cartridge and embedded casing

- Impellers

- Balanced impeller, reduced thrust loads

The ClydeUnion Pumps concrete volute pump is one of the most reliable cooling water pumps on the market. Working with civil contractors has led to a design that merges the needs of civil and mechanical disciplines. Designed for high flow applications, the concrete volute pump reduces the number of pumps required, whilst achieving high availability and efficiency. The main advantages are to be found in construction, total cost, handling, installation and maintenance:

- Suitable for a higher flow per pump, resulting in fewer pumps being required

- Pump casing is predominantly produced in concrete, eliminating corrosion problems often experienced with suspended bowl pumps (especially in hot sea water)

- Pump construction is concurrent with intake and pumphouse structures, ensuring correctness of mechanical and civil interfaces

- Volute design is simplified, using flat surfaces where possible and minimising the number of concrete pours

- Approaching 100% availability achieved on all installations

- Installed efficiency is higher than conventional bowl pumps - concrete volute pumps are larger, more efficient and do not encounter column or bend losses

- The concrete volute design boasts a minimum of 10–12 years between internal inspections

- Large scale cooling water duties

- High flow water intake systems

- High flow water transfer duties

- Land irrigation / drainages schemes

- Flood control systems

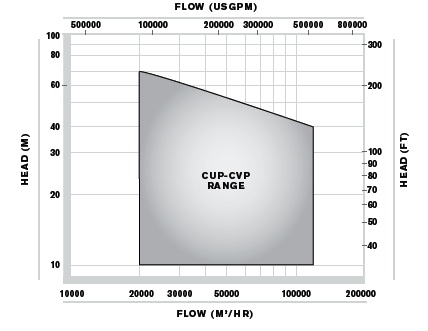

- Capacity: up to 120,000 m3/hr / 530,000 gpm

- Delivery Head: up to 70 m / 230 feet

- Temperature: up to 80 oC / 180 oF

- Speeds: up to 330 rpm

- Flange drilling: BS or ANSI