- Home

- Companies

- P S Analytical Limited

- Applications

- Mercury analysis solutions for ...

Mercury analysis solutions for petrochemical laboratory industry - Chemical & Pharmaceuticals - Petrochemical

Using Atomic Fluorescence Spectrometry (AFS) in the laboratory for the determination of Mercury in Petrochemical Samples.

It has never been more important to understand the fate of mercury (Hg) in all aspects of oil and gas exploration, refining, production, and waste management. Coupled with concerns of worker exposure to Hg vapour, an array of sampling and analytical systems may be required in order to successfully monitor and measure this element at trace and ultra-trace concentrations.

Some of the key issues with Hg in petrochemical samples;

- Mercury is corrosive to metals, particularly aluminium, and is implicated to affect a whole range of gas plant components. In some cases, the corrosive nature of Hg has caused catastrophic plant failure.

- The presence of Hg in feedstocks can destroy expensive downstream catalysts if not removed beforehand.

- The exposure of Hg vapours to workers the OH&S concerns are well documented and are often a key driver in operational decisions.

- For the above reasons, Hg removal beds operate and are key components in many plant processes. Monitoring the Hg inlet and outlet of these beds is important in managing these removal technologies.

- The presence of Hg in petrochemical aqueous waste streams (produced waters) is under increasing scrutiny and, in most parts of the world, discharge regulations require monitoring and reporting protocols to ensure company compliance in line with environmental guidelines.

From the above it is clear that Hg may be present in air, hydrocarbon gases & liquids and produced waters. Representative collection of the sample and subsequent analysis is not trivial, and a number of approaches may be required to enable the analysis of these varied sample matrices.

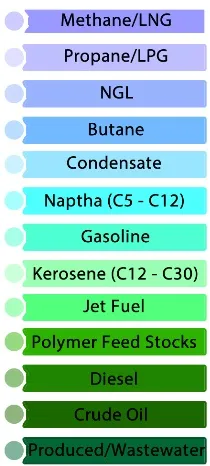

In most cases there is a requirement to determine Total Mercury in one or several of the sample matrices shown on the left.

Under Standard Temperature and Pressure (STP) conditions the desired sample, maybe a gas, liquid or solid and so various collection strategies are required to collect and prepare a representative sample.

This may be complicated further if the sample is at high pressure and temperature (e.g. in gas plant process conditions) and further careful consideration is needed to ensure the sample is handled correctly and that the Hg is not “lost” during the analytical procedure.

P S Analytical has an extensive library of applications in this market. A few examples are provided in the Table below;

Determination of Mercury in……

P S Analytical 10.525 Sir Galahad continues to provide world class analytical performance.

The Sir Galahad may be employed as a stand-alone analyser or in conjunction with sample handling equipment and modules depending on the application. The system is often integrated into online systems for those applications requiring constant Hg monitoring and offers unparalleled performance. The Sir Galahad uses AFS, a sensitive technique, that allows for sub ppt determinations.

Detection Performance - Sir Galahad AFS

- Detection limit Hg < 0.1 ng m-3

- Analytical Range Hg 0.1 ng m-3 to 3 mg m-3

A range of accessories and modules may be used in conjunction with the Sir Galahad analyser. These accessories are required for successful calibration and effective sample handling from a variety of petrochemical matrices.

P S Analytical 10.555 Manual Calibration Kit

The calibration kit consists of a calibration glass vessel, a thermometer, and a set of gas tight syringes. By varying the injection volume, standard calibration curves are quickly and easily produced.

In addition to manual calibration we offer automated calibration systems. These systems couple directly to the Sir Galahad and operate on the principle of diluting a saturated source of mercury at known temperature into the concentration range of interest. The flowrates are controlled using two mass flow controllers.

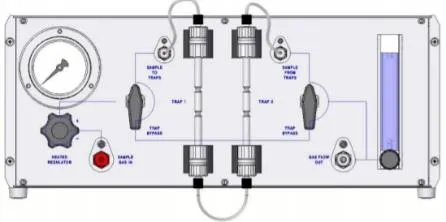

The heated pressure let down (PLD) system is an important accessory for those taking field samples at elevated temperature and pressure and finds particular use in the oil and gas sector. The PLD is compliant with the latest ATEX and IECEx standards and is suitable for use in Zone 1 hazardous area. The PLD collects the sample at process conditions and reduces the pressure using a heated regulator and large sample bypass facility.

The PLD is taken to the sample point and sample gas is passed across the gold trap. Unlimited volumes of gases may be collected. The PLD may also be used in the lab to safely collect samples from high pressure SilcoNert® sample cylinders.

The employment of the Sir Galahad with the PLD is well suited for ASTM D6350 standard methods.

This accessory is similar to the PLD but must be used in non-hazardous areas. This module enables the laboratory analysis of mercury in liquefied petroleum gas samples. Typically, a sample is delivered to the instrument as a liquid in a pressurised sample vessel or bomb. The system is designed for manual sample collection onto remote Amasil™ traps for subsequent analyse with the Sir Galahad.

Liquid hydrocarbon samples (at STP) are injected into a vaporisation chamber held at 400ºC. The vapour produced is continuously swept by a carrier gas through the heated Amasil trap where any Hg that is present within the vapour is collected. After collection the trap is heated to 900ºC, releasing the Hg. The Hg is collected onto a secondary Amasil trap and subsequently presented to the Sir Galahad. Automation options are available for high throughput requirements.

This system is used in conjunction with the PSA 10.515 preconcentration unit. It has the unique capability of taking the sample at process conditions (from a sample cylinder or bomb) and injecting directly without depressurising the sample. This is an important aspect when analysing pressurised samples that may be gas/liquid mixtures and means that samples do not have to be collected and subsequently analysed in separate phases. Such samples include naphtha, unstabilised condensates, and liquefied gas samples such as LNG, LPG and butane.

For all aqueous samples (such as produced or wastewaters), high boiling point hydrocarbon liquids and for solid materials such as mercury removal bed resins, a different sample handling approach is required.

In these cases, the samples are acid digested, usually at elevated temperatures. The resulting digested samples are analysed using cold-vapour AFS with the P S Analytical Millennium Merlin 10.025

The standard system provides a limit of detection of 0.1ng/L and a linear working range from 0.1ng/L to 10mg/L. The analysers are robust, easy to operate and are ideally suited to many sample types.

Coupling Atomic Fluorescence Spectrometry (AFS) with either cold vapour generation or hydride generation has been PSA’s core competency for over 35 years, PSA offers powerful analytical tools to help laboratories, research teams and regulators alike with these critical determinations.