Handy Device Medical Technology

Great technology in a handy device. The plasma care product line is handily designed for mobile use by doctors and nurses. The device is functional, user-friendly and at the same time aesthetically designed. The spacer – also known as spacer – guarantees hygienic use.

- The cover with touch button to turn the device on and off, the housing with ergonomic design includes all the electrics and control of the device.

- The plasma source – is the heart of plasma care®, where the plasma is generated by microdejections. It is equipped with wafer-thin ceramic plates and sensitive electrical contacts.

- The sterile disposable spacer is used per treatment. It is mounted on the plasma source and guarantees the hygienic use of the device – even in busy everyday practice. A new spacer must be used for each treatment, which is ensured by an RFID unit (radio-frequency identification); it turns off the device when a spacer is used repeatedly and displays this accordingly in the user interface..

- Docking station: The batteries of the plasma care® are charged wirelessly through the docking station to avoid the ingress of liquid and dirt into the housing. Inductive charging ensures that the user and the patient cannot have contact with live components. Once charged, the battery lasts for about 120 applications

- The power supply: The power supply is connected to the docking station

- Training spacer – it can be used to get to know the product: This spacer can be put on repeatedly, since it is closed, no cold plasma escapes.

All housing parts are made of medical plastics. The surfaces are made of biocompatible plastics. The controls and LED lights are integrated into the housing in such a way that there are no openings – the advantages: dirt cannot be placed, deposits are avoided, easy cleaning with wipe disinfection is made possible.

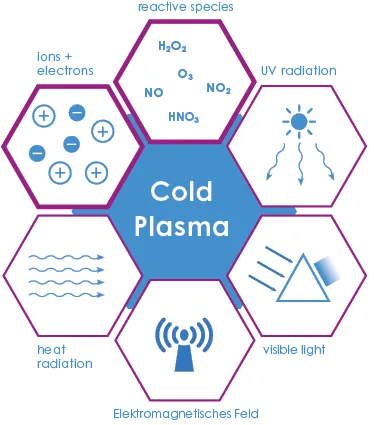

Plasma is an ionized gas, i.e. it contains charged particles. It is formed from a gas to which energy is supplied, usually in the form of heat, and is often referred to as the fourth state of matter. Natural examples of plasmas are the sun or lightning on Earth.

Cold atmospheric plasmas (CAP) are partially ionized gases, i.e. only one particle from 1·109 is ionized. The advantage of these cold atmospheric plasmas is that they can persist at room temperature and atmospheric pressure. Plasma care® uses patented thin-film technology, a further development of surface micro-discharge technology (SMD). The Plasma Source Unit consists of a high-voltage electrode, a dielectric and the grounded structured electrode. By applying a high voltage of 3.5 kV, micro-discharges with an expansion of a few millimeters occur in the electrode structured in squares. These ionize the gas and thus generate the plasma.

The composition of a cold atmospheric plasma is not a fixed quantity, but can be influenced, among other things, by the choice of plasma source and its operating parameters. This is referred to as the so-called “plasma design”. In the case of SMD cold plasma technology, which is used in plasma care® for wound treatment, the plasma design was chosen in such a way that a high bactericidal effect is achieved in vitro and tissue damage is avoided

Similar to Shimizu et al. 2017 DOI: 10.1615/PlasmaMed.2017019455), investigations were carried out with the plasma care® plasma source in so-called oxygen and nitrogen mode to determine the optimal operating parameters for maximum effectiveness and safety. With the help of these and extensive further investigations, plasma care® was carefully developed for its intended purpose.