Himed products

Biomaterials

Himed - Model B-TCP - Beta-Tricalcium Phosphate for Bone Repair

Beta-tricalcium phosphate (β-TCP) is a calcium phosphate biomaterial noted for its bioactive and resorbable properties, which make it highly effective in applications such as bone grafting and implants. It supports bone regeneration due to its osteoconductive nature, acting as a scaffold for natural bone to replace over time. By adjusting the porosity and particle size of β-TCP, its resorption rate can be controlled to fit specific medical applications, including orthopedic and dental fields. β-TCP can integrate with other biomaterials, such as hydroxyapatite and polymers like PLGA, enhancing its mechanical and resorption dynamics. Its chemical composition mirrors that of natural bone, promoting biocompatibility and integration with bone tissue without triggering immune responses. β-TCP's unique qualities, such as osteoinductive properties, allow for the differentiation of progenitor cells to support bone growth, even where bone tissue is absent, making it an excellent choice for applications in spinal fusion, dental implants, and trauma implants.

Himed - Synthetic Hydroxyapatite (HA) for Biomedical Applications

Himed specializes in high-quality synthetic hydroxyapatite (HA), a calcium phosphate biomaterial known for its biocompatibility and bioactivity, making it highly suitable for bone regeneration, dental reconstruction, and orthopedic implants. Unlike natural forms, Himed's HA is synthetically manufactured to ensure consistent stoichiometry, essential for precise clinical and engineering applications. The company's HA is produced under GMP guidelines and conforms to ISO 13485:2016 and ASTM F1185 standards with a purity of ≥96%, ensuring reliable batch-to-batch consistency demanded by medical and dental markets. Offering a comprehensive array of forms including powders, granules, cast solids, and porous shapes, Himed's HA supports diverse applications from scaffolds to implant coatings. Furthermore, the material's tunable attributes, like particle size and crystallinity, enhance its role in composite systems, often coupled with polymers like PEEK for improved mechanical properties. Himed also provides customization services, allowing for engineered performance tailored to specific needs.

Himed - Calcium Phosphates

At Himed, we have been creating and customizing bioactive calcium phosphate materials for over 30 years. Across the globe, our biomaterials are used in medical devices, dental implants, orthopedic implants, prosthetics, and in laboratories each day, which is why we never compromise in our commitment to precision manufacturing and the highest-quality end products. If you have unique customization requests we will work with you to find innovative materials solutions to meet your exact needs for an optimized product.

Forms

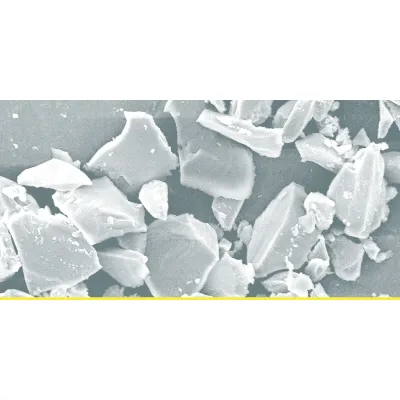

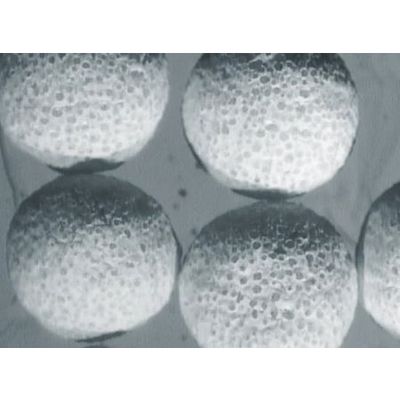

Himed - Coating Powders

Powders used specifically for surface coatings can be produced in spherical forms to improve flowability and uniformity of application. Himed produces its own coating powders and offers on-site hydroxyapatite coating solutions for small and high volume lots.

Surfaces

MATRIX MCD - Biocompatible Micro Abrasive for Medical Implants

MATRIX MCD® is a specialized biocompatible micro abrasive blasting solution designed for titanium and titanium alloy medical devices, particularly in the dental and orthopedic sectors. Utilizing a proprietary multi-phase calcium phosphate (MCD) abrasive, it delivers precise surface texturing without compromising the structural integrity of the implant. Unlike conventional abrasive blasting methods, which may leave residual contaminants, MATRIX MCD® ensures a residue-free finish, complying with ASTM F86 passivation standards. This technology facilitates enhanced osseointegration by increasing bone-to-implant contact area, which is crucial for implant stability. It is applicable in both traditional metallurgical and additive manufacturing processes. The system enables adjustable parameters like particle size, allowing customization for specific implant designs. Furthermore, MATRIX MCD® can integrate with other surface finishing techniques, such as anodized coloring or hydroxyapatite coatings, to meet diverse clinical needs, while maintaining high volume production efficiency through automated systems.