- Home

- Equipment

- latamerica

- electrode array

Refine by

Locations

- Latin America

- Antigua & Barbuda

- Argentina

- Aruba

- Bahamas

- Barbados

- Belize

- Bolivia

- Brazil

- Cayman Islands

- Chile

- Colombia

- Costa Rica

- Cuba

- Dominica

- Dominican Republic

- Ecuador

- El Salvador

- Grenada

- Guatemala

- Guyana

- Haiti

- Honduras

- Jamaica

- Mexico

- Netherlands Antilles

- Nicaragua

- Panama

- Paraguay

- Peru

- Puerto Rico

- St. Kitts & Nevis

- St. Lucia

- St. Vincent & The Grenadines

- Suriname

- Trinidad

- Uruguay

- Venezuela

Electrode Array Equipment & Supplies In Latin America

24 equipment items found

Manufactured by:Senzime AB Uppsala based inUppsala, SWEDEN

TetraSens electrode array has two proximal stimulating electrodes, one recording electrode and one reference electrode. The application is easy and quick. TetraSens electrode array is for single-patient use in order to avoid cross contamination. The electrodes ...

Manufactured by:Bmseed based inMesa, ARIZONA (USA)

Mechanics Module: strain rate up to 1/s, strain up to 20%. Imaging Module: frame rate: 150fps. Electrophysiology Module: 2x60 channels. Physiological stretch of cells to reproduce the environment of cells inside the body; assessment of cell health, function, and maturity using electrophysiological measurements; visualization of cells and cellular processes during ...

Manufactured by:Bmseed based inMesa, ARIZONA (USA)

Mechanics Module: strain rate up to 80/s, strain up to 50%. Imaging Module: frame rate: 2,000fps. Electrophysiology Module: 2x60 channels. Very rapid pathological stretch of cells to reproduce biomechanics of an injury such as traumatic brain injury (TBI) or spinal cord injury (SCI); assessment of cell health and function using electrophysiological measurements; visualization of cells and ...

Manufactured by:Bmseed based inMesa, ARIZONA (USA)

Mechanics Module: strain rate up to 50/s, strain up to 50%. Imaging Module: frame rate: 2,000fps. Electrophysiology Module: 2x60 channels. Pathological stretch of cells to reproduce biomechanics of an injury such as traumatic brain injury (TBI) or spinal cord injury (SCI); assessment of cell health and function using electrophysiological measurements; visualization of cells and cellular ...

Manufactured by:Ardiem Medical, Inc. based inEast Indiana, PENNSYLVANIA (USA)

Standard Spiral Nerve Cuff Electrode with four electrodes arrayed radially around the cuff diameter (4 mm diameter electrode ...

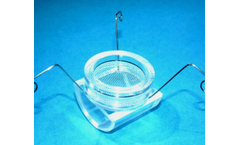

Manufactured by:Beacon Innovation International Inc (BIII) based inMarkham, ONTARIO (CANADA)

The Brain Slice Keeper AM has been designed with an integral heater and sensor element for preincubation of brain slices prior to transfer into recording chambers. In addition there is provision of inlet and outlet tubes to an external chamber incorporating multi-electrode ...

Manufactured by:Sarclad based inRotherham, UNITED KINGDOM

The Rolltex Multi Servo Array (MSA) from Sarclad is an advanced Electro-Discharge Texturing (EDT) solution. Catering to surface critical strip applications, such as automotive external panels, the MSA ensures precise roll texture control. A significant advancement over standard EDT technology, the MSA features customizable electrode arrays, with ...

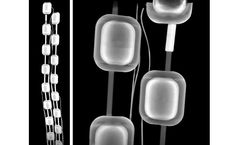

by:Synchron, Inc. based inBrooklyn, NEW YORK (USA)

Our Neuro EP platform is built on the stentrode™, an endovascular electrode array. It is designed to record or stimulate the brain or nerves from within the blood vessels. The device is designed to become incorporated into the wall of the blood vessel like a tattoo. Similar to a stent, it is designed not to cause long term inflammation or trauma to the ...

Manufactured by:Spes Medica based inGenova, ITALY

Intracranial surface electrodes or subdural cortical electrodes are used for stimulation and recording of central nervous system signals. Intracranial monitoring is used to identify and map functional areas of the brain during pre- and post-surgical phases and during surgical removal of brain tumors. The surface of the intracranial electrodes are ...

Manufactured by:Pulse Technologies based inQuakertown, PENNSYLVANIA (USA)

Electrodes and microelectrode arrays in most long-term implantable neurostimulation devices demand low impedance for sensing and recording applications, and high charge injection capacity to achieve safe and reversible stimulation. Electrodes with larger geometric surface area perform better, but they take up more space, limit the device’s ...

Manufactured by:BrainXell based inMadison, WISCONSIN (USA)

Origin: Human iPSC line. Products: 2M Viable Cells/Vial - Standard (BX-0650). 1M Viable Cells/Vial - Standard (BX-0650e). Contents: 1 vial of cells and corresponding BrainXell supplement. ...

Manufactured by:NeuroMetrix, Inc. based inWoburn, MASSACHUSETTS (USA)

A point-of-care diagnostic platform that is primarily used to screen for and confirm entrapment of the median nerve, which is the hallmark sign of carpal tunnel ...

Manufactured by:BrainXell based inMadison, WISCONSIN (USA)

Origin: Human iPSC line. Products: 5M Viable Cells/Vial - Standard (BX-0300). 1M Viable Cells/Vial - Standard (BX-0300e). 2M Viable Cells/Vial - GFP expressing (BX-0301). Contents: 1 vial of cells and corresponding BrainXell supplements, ...

Manufactured by:BrainXell based inMadison, WISCONSIN (USA)

Origin: Human iPSC line. Products: 5M Viable Cells/Vial - Standard (BX-0100). 1M Viable Cells/Vial - Standard (BX-0100e). 2M Viable Cells/Vial - GFP expressing (BX-0101). Contents: 1 vial of cells and corresponding BrainXell supplements. ...

Manufactured by:BrainXell based inMadison, WISCONSIN (USA)

Origin: Human iPSC line. Products: 5M Viable Cells/Vial - Standard (BX-0350). 2M Viable Cells/Vial - GFP (BX-0351). Contents: 1 vial of cells and corresponding BrainXell ...

Manufactured by:Precision Neuroscience based inManhattan, NEW YORK (USA)

The Layer 7 Cortical Interface by Precision is an advanced microelectrode array system designed to interface with the brain's cortical surface for brain-computer interface (BCI) applications. This system is comprised of thin film microelectrode arrays engineered for a minimally invasive implantation that conforms to the brain's surface without causing tissue ...

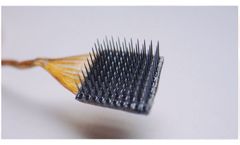

Manufactured by:Blackrock Neurotech based inSalt Lake City, UTAH (USA)

With its high-channel count, superior signal-to-noise ratio, and exceptional quality, the Utah Array powers the most ambitious neuroscience research. Utilizing the latest advancements in neurotechnology, its electrodes are capable of recording and stimulating individual neurons or groups of neurons with maximum ...

Manufactured by:X-trodes based inHerzliya, ISRAEL

The X-trodes methodology is based on innovative flexible sensors, a miniaturized high-end, low noise Bluetooth amplifier, and cloud-based artificial intelligence analysis, easily accessible via PC, tablet or smartphone. Using a simple to use application programming interface (API), our technology simplifies the entire data analysis and visualization process for maximum convenience. All data is ...

Manufactured by:Viora based in, NEW YORK (USA)

V-FR Handpiece - Beyond Fractional Results! Fractional Treatments for Complete Skincare. Fractional RF treatments allow for safer, more comfortable treatments for patients looking for skin resurfacing, rejuvenation, acne scar clearance, wrinkle reduction and pigmentation disorders. Now with the Viora V-FR Handpiece you can offer your clients an effective, minimally invasive solution to more ...

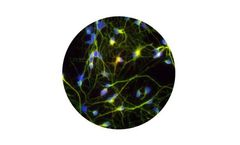

Manufactured by:Ncardia Services B.V. based inLeiden, NETHERLANDS

Cortical neurons play a vital role in many neurodegenerative diseases, including Alzheimer’s disease. Human iPSC-derived cortical neurons can be co-cultured with astrocytes and microglia to model neurodegenerative diseases. Our team can manufacture cortical neurons at scale from the iPSC line that best fits your project or work with off-the-shelf Ncyte Cortical Neurons to support your drug ...