Show results for

Refine by

Brain Imaging Software Available In Canada

11 software items found

by:Deep01 Limited based inNew Taipei, TAIWAN

An AI-powered CDSS (Clinical Decision Support System) identifies intracranial hemorrhage (ICH, brain bleed) and other critical findings on head CT scans. By analyzing brain CT images, DeepCT helps doctors identify the symptoms of patients quickly and accurately. ...

by:Cortechs.ai based inSan Diego, CALIFORNIA (USA)

OnQ Neuro is FDA-cleared post-processing software used by radiologists, oncologists, and other clinicians to assist with the analysis and quantification of MR images of brain ...

by:Cortechs.ai based inSan Diego, CALIFORNIA (USA)

For the assessment of brain volumes for multiple sclerosis and age-associated neurodegenerative conditions. The NeuroQuant Multi-Structure Atrophy Report presents volumetric information for whole brain, superior lateral ventricles, thalamus, cortical gray matter, cerebral white matter, cerebral white matter hypointensities, 3d ventricle, hippocampus, and inferior lateral ventricles. The MSA ...

by:Cortechs.ai based inSan Diego, CALIFORNIA (USA)

For the assessment of traumatic brain injury and other neurodegenerative conditions. The NeuroQuant TBA Report provides physicians a quick reference and in-depth look on regional and global brain structure volumes, which could occur as a result of a brain injury or neurodegenerative disease, by providing volume measurements of 47 brain structures for both the right and left hemisphere, total ...

by:Cortechs.ai based inSan Diego, CALIFORNIA (USA)

For the assessment of multiple sclerosis and other neurodegenerative conditions. Automatically label, visualize and obtain the volumetric quantification of segmentable brain structures and lesions from MRI brain studies—within minutes. NeuroQuant MS combines T2 FLAIR with 3D T1 MR images to enhance your ability to identify and monitor the ...

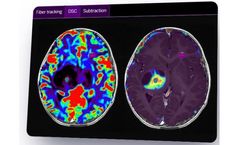

by:Olea Medical based inLa Ciotat, FRANCE

Our breakthrough neuroimaging tools seamlessly integrate into your daily clinical CT & MRI workflows to assist you in every step of your decision-making in pre- and post-treatment ...

by:Turing Medical Technologies, Inc. based inSt. Louis, ALABAMA (USA)

The FIRMM-pix system is designed to enhance MRI imaging accuracy by addressing the challenges of motion-induced image degradation, a common obstacle in brain MRIs. By integrating biofeedback and gamification, FIRMM-pix offers an innovative approach to train patients, including children, to minimize movements during scans. ...

by:SpinTech, Inc. based inBingham, MICHIGAN (USA)

Revolutionize Your Radiology Department. One software to streamline your radiology department’s workflows, increase patient throughput, improve patient experience, and deliver enhanced, quantitative MRI to improve neuroimaging ...

by:Qynapse based inParis, FRANCE

The software is intended to be used by medical personnel or neuroimaging trained personnel to support diagnosis of central nervous system diseases. Available for research use only and protected by 3 patents, QyPredict has the potential to improve targeted patient selection in clinical trials and prediction of disease progression in patients. QyPredict is the future, and the future is ...

Manufactured by:BrainMaster Technologies, Inc. based inBedford, OHIO (USA)

BrainAvatar incorporates technology including BrainMaster’s Discovery, Freedom and Atlantis hardware devices, extensive signal processing and graphics software, and an exclusive high-speed sLORETA (standardized low-resolution electromagnetic brain tomography) voxel processor and 3D image projector. BrainAvatar is a full-featured clinical system, registered ...

by:Viz.ai, Inc. based inSan Francisco, CALIFORNIA (USA)

Viz CTP uses advanced imaging technology to automatically analyze CT perfusion images of the brain, produce parametric color maps, and calculate CT perfusion ...